What are the benefits of using PVC pipe in construction?

In the construction industry, the adoption of PVC pipe has gained significant traction. Experts praise its advantages. One such authority, Dr. Emily Carter, states, "PVC pipe offers unmatched durability and flexibility for various applications." This versatility is essential in modern building projects.

PVC pipe is lightweight yet strong. This combination simplifies transport and installation. It's resistant to corrosion and chemicals, which extends its life. However, some argue that improper disposal of PVC products poses environmental risks. We must consider the entire lifecycle of materials used.

In conclusion, the benefits of PVC pipe are evident. They contribute to efficiency and sustainability in construction. Yet, ongoing discussions about environmental impact remind us to seek improvements. Balancing benefits with responsibilities is crucial for the industry's future.

Benefits of PVC Pipe: Cost-Effectiveness in Construction Projects

PVC pipe is becoming a popular choice in construction due to its cost-effectiveness. It is lightweight, making it easy to transport and install. Many construction projects can save on labor costs because of this benefit. Workers can handle PVC pipes without heavy machinery. This adaptability also reduces time on site, leading to faster project completion.

In addition to being budget-friendly, PVC pipes are durable. They resist corrosion and can withstand harsh weather conditions. This longevity reduces the need for replacements and long-term maintenance. However, some may overlook the environmental impact of PVC production. While it can save money initially, it's essential to consider sustainability.

Moreover, PVC pipes are versatile. They can be used for plumbing, drainage, and even electrical conduits. This wide range means fewer materials needed, which can cut costs further. But one must reflect on local regulations. Some areas have specific guidelines regarding PVC use. This might complicate projects for builders who don’t pay attention.

Durability and Longevity of PVC Pipes in Various Environmental Conditions

When it comes to construction, the choice of materials significantly impacts durability. PVC pipes stand out for their longevity, especially in various environmental conditions. According to industry reports, these pipes can last over 50 years when properly installed. Their resistance to corrosion and chemical damage makes them an attractive option in harsh environments. For instance, in coastal regions, where saltwater can erode other materials, PVC remains largely unaffected.

Moreover, PVC pipes maintain their integrity under extreme temperatures, ranging from -15°C to over 60°C. This thermal stability ensures their effectiveness in diverse climates. A study by the Plastic Pipe and Fittings Association reveals that exposed PVC pipes can still perform well, despite UV exposure. However, it's essential to ensure proper installation techniques, as improper fittings can lead to failure. Some contractors report challenges with creating watertight seals, emphasizing the need for careful handling.

One area that requires reflection is the environmental impact of PVC production. While PVC pipes are durable, the manufacturing process can be resource-intensive. Recyclability is a growing concern. Some manufacturers are exploring more sustainable practices, but the industry still faces criticism. Balancing the benefits of PVC's longevity with its ecological footprint remains a challenge.

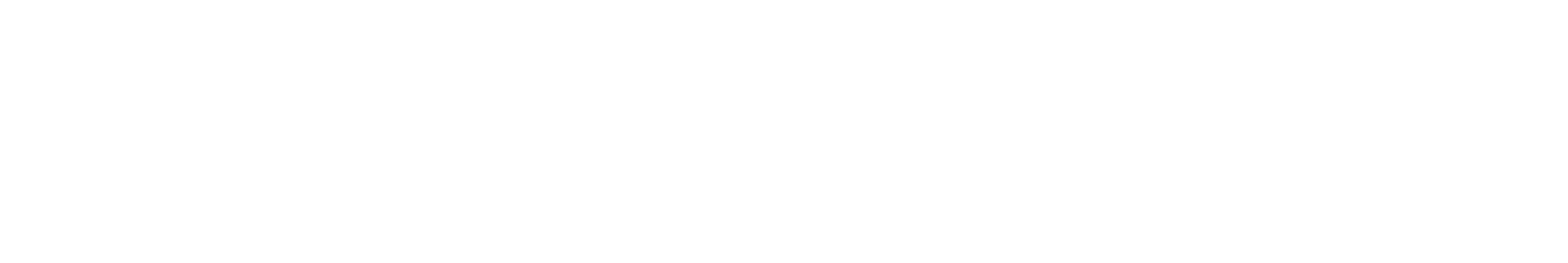

Lightweight Nature of PVC for Easy Transport and Installation

When it comes to construction, the lightweight nature of PVC pipe makes it a game-changer. This material is significantly lighter than traditional options like metal or concrete. Transporting PVC pipes is much easier. Fewer resources are needed for handling and moving. Workers can lift and position these pipes without specialized equipment. This ease of transport can speed up construction schedules.

Installation benefits are also notable. Workers can install PVC pipes quickly and efficiently. The lightweight characteristic reduces fatigue, leading to fewer errors. However, this ease can sometimes lead to carelessness. Proper handling is essential to maintain integrity during installation. If not handled correctly, the pipes may sustain damage before use.

Moreover, lightweight materials can sometimes feel less durable. While PVC is resistant to corrosion, some may question its strength. It's essential to consider specific project needs. PVC pipes are great for various applications but may not suit every situation. Balancing benefits with potential limitations is critical for successful construction projects.

Corrosion and Chemical Resistance of PVC Pipes Compared to Other Materials

PVC pipes are notable for their exceptional corrosion resistance. Unlike metal pipes, PVC does not rust or corrode. This property extends their longevity. For example, a study by the American Society of Civil Engineers highlights that PVC can last over 100 years under proper conditions. This durability is a significant advantage for construction projects that demand long-lasting materials.

When it comes to chemical resistance, PVC also excels. It can withstand various harsh chemicals, making it ideal for industrial applications. A report from the Plastics Industry Association notes that PVC pipes resist acids and bases effectively. Many traditional materials, like steel, cannot handle these substances. This resistance often leads to lower maintenance costs over time. However, some may argue PVC's brittle nature under extreme temperatures can be a downside.

Overall, the benefits of PVC pipes are clear, yet they are not without flaws. While they serve well in many applications, careful consideration must be taken in regions with extreme climates. Balancing these strengths and weaknesses is crucial for engineers in choosing the right material for any construction project.

Benefits of Using PVC Pipe in Construction: Corrosion and Chemical Resistance

Energy Efficiency and Low Maintenance Costs Associated with PVC Use

PVC pipe has become a popular choice in construction due to its energy-efficient properties. It’s lightweight and easy to handle, which can reduce energy consumption during transport and installation. Contractors find that using PVC can lead to lower labor costs as well. This material doesn’t require extensive tools or equipment, speeding up the building process.

In addition to energy efficiency, PVC pipe is low maintenance, which appeals to many builders. It resists corrosion and does not require regular replacements like metal pipes do. This quality lowers long-term maintenance costs significantly. There may be concerns about its environmental impact, though. While PVC is durable, the production process has raised questions. Balancing these concerns with the overall benefits is essential for sustainable construction practices.

Despite these advantages, some challenges remain. For instance, the heat tolerance of PVC may not be suitable for all climates. Additionally, proper installation is crucial to prevent leaks. A few missteps can lead to costly repairs later on. Overall, while PVC offers efficiency and low maintenance, ongoing discussions about its environmental implications linger.

Benefits of Using PVC Pipe in Construction

| Benefit | Description | Impact on Construction |

|---|---|---|

| Energy Efficiency | PVC pipes are excellent insulators, reducing heat loss and cooling costs. | Lower energy consumption leads to reduced operational costs of buildings. |

| Low Maintenance Cost | PVC does not rust, corrode or rot, minimizing the need for repairs. | Saves on long-term maintenance and replacement costs. |

| Lightweight | Easier to handle and install compared to metal pipes. | Reduces labor costs and accelerates project timelines. |

| Chemical Resistance | Highly resistant to a variety of chemicals, water, and gases. | Enhances durability of plumbing systems and extends service life. |

| Eco-Friendly | Can be recycled and has a lower environmental impact compared to other materials. | Support for sustainable building practices. |

Related Posts

-

Top 10 Uses of PVC Well Pipe for Water Distribution and Irrigation?

-

2025 Top 10 PVC Tubes Innovations Driving the Market with 10 Billion Dollar Growth Potential

-

How to Choose the Right PVC Pipe for Your Home Project

-

What is PVC Pipe and Its Uses in Construction and Plumbing?

-

Understanding the Rapid Growth of PVC Supplies Market with Insights from Industry Trends and Data Analysis

-

2025 How to Choose the Best PVC Well Pipe for Your Water System