Top 10 Best Water Well Pipes: Durable Solutions for Your Water Supply Needs

In the quest for reliable and efficient water supply solutions, the choice of water well pipes is paramount. According to industry expert Dr. John Harper, a leading authority in water resource management, "Selecting the right water well pipe is essential not only for the longevity of the well but also for ensuring a clean and consistent water supply." His insights underline the importance of durability and performance in the materials used for these vital components.

With a myriad of options available, it can be overwhelming to determine which water well pipes are best suited for specific needs. From PVC to steel, each material offers unique advantages that can significantly affect the efficiency and longevity of a water well system. Understanding the characteristics of these pipes is crucial for anyone involved in water well construction or maintenance.

This article delves into the top 10 best water well pipes available on the market today, highlighting their features, benefits, and performance metrics. Whether you are a homeowner, a well contractor, or an environmental consultant, being informed about the best solutions will help you make the right choices for sustainable water supply management.

Types of Water Well Pipes: A Comprehensive Overview

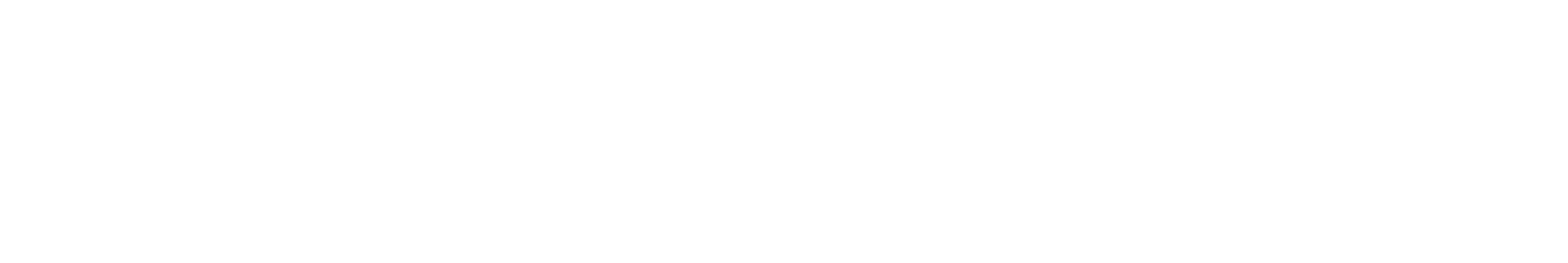

When it comes to selecting the right pipes for water well systems, understanding the various types available is essential. The most common materials used for water well pipes include PVC, steel, and polyethylene. PVC pipes are popular due to their lightweight nature, corrosion resistance, and affordability. They are suitable for shallow wells and have a long lifespan, making them an attractive option for many homeowners. However, their flexural strength can be a limitation under high water pressure, which might necessitate consideration of other materials.

Steel pipes, on the other hand, offer exceptional durability and strength, making them ideal for deep well applications. They are resistant to impact and can withstand the harsh conditions of underground environments. However, steel is prone to corrosion, so protective coatings are often necessary to prolong its lifespan. Polyethylene pipes enjoy a growing popularity due to their flexibility, resistance to chemicals, and ease of installation. They are particularly advantageous in situations where bending is required or where ground conditions are not favorable for rigid pipes. Choosing the right material ultimately depends on factors such as well depth, environmental conditions, and water quality considerations, ensuring a reliable water supply for years to come.

Top 10 Best Water Well Pipes: Durable Solutions for Your Water Supply Needs

| Pipe Type | Material | Diameter (inches) | Length (feet) | Durability Rating | Cost per Foot |

|---|---|---|---|---|---|

| PVC Pipe | PVC | 4 | 20 | High | $0.80 |

| Steel Pipe | Steel | 6 | 30 | Very High | $1.50 |

| Copper Pipe | Copper | 2 | 15 | High | $2.00 |

| Fiberglass Pipe | Fiberglass | 4 | 25 | High | $1.10 |

| Polyethylene Pipe | PE | 3 | 50 | Medium | $0.90 |

| Galvanized Pipe | Galvanized Steel | 4 | 40 | Medium | $1.20 |

| Concrete Pipe | Concrete | 8 | 10 | Very High | $3.00 |

| CPVC Pipe | CPVC | 2 | 20 | Medium | $0.85 |

| HDPE Pipe | HDPE | 6 | 60 | High | $1.40 |

| Aluminum Pipe | Aluminum | 3 | 30 | Medium | $1.75 |

Factors to Consider When Choosing Water Well Pipes

When choosing water well pipes, several critical factors must be taken into account to ensure a reliable and efficient water supply. First, consider the material of the pipes. Common options include PVC, steel, and polyethylene, each with its own strengths and weaknesses. PVC is lightweight and resistant to corrosion, whereas steel is durable and can withstand higher pressures, making it a popular choice for deeper wells. Polyethylene is flexible and easy to install, making it ideal for projects that require bending or maneuvering around obstacles.

Another essential factor is the pipe diameter. The diameter impacts the flow rate and volume of water that can be extracted from the well. Choosing the right diameter is essential to match your water usage needs, as a pipe that is too narrow may restrict flow, while one that is too wide could lead to other complications. Additionally, consider the depth of the well and the water table level when selecting the appropriate pipe size.

Tips: When selecting water well pipes, always check for certifications or standards that indicate quality. Pipe longevity can be affected by environmental factors such as soil type and pH levels, so it's beneficial to conduct a thorough analysis of your specific well site. Additionally, ensure you have the necessary fittings and accessories for installation, as these are crucial for maintaining a sealed and effective water system.

Top 10 Best Water Well Pipes: Durability Comparison

Top Durable Materials for Water Well Pipes

When it comes to selecting water well pipes, the material used is crucial for ensuring durability and long-term performance. Among the top materials highly regarded in the industry are PVC, which is lightweight and resistant to corrosion, and stainless steel, known for its strength and longevity. According to a report by the National Ground Water Association, properly selected well casing materials can increase the lifespan of your water supply system significantly, lowering maintenance costs and enhancing reliability.

Another worthy option is HDPE (high-density polyethylene), which offers exceptional resistance to chemicals and environmental stress. The American Society for Testing and Materials (ASTM) outlines that HDPE pipes can endure temperatures ranging from -40°F to 140°F, making them versatile for various climates. It is essential to consider factors such as groundwater chemistry and temperature variations when deciding on your well pipe material.

**Tips:** Always consult with a groundwater professional to analyze the specific conditions of your site before making a choice. Additionally, ensure that the installation process adheres to local regulations and standards to prevent future issues. Regular inspections and maintenance of well pipes can also extend their lifespan and ensure a sustainable water supply.

Installation Techniques for Optimal Water Well Performance

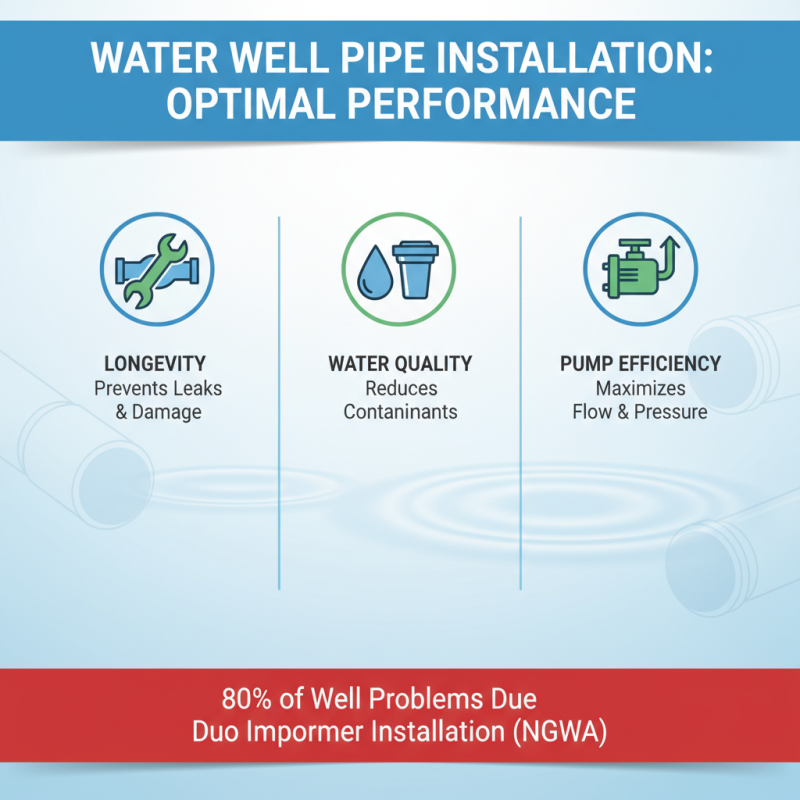

When it comes to the installation of water well pipes, ensuring optimal performance is crucial to maintain a reliable and efficient water supply. Proper installation techniques not only enhance the longevity of the well system but also maximize water quality and pump efficiency. According to the National Ground Water Association, approximately 80% of the problems reported in water wells can be traced back to improper installation practices. Therefore, focusing on detailed methods during installation can prevent future complications.

One essential technique is the correct placement of the well casing. The casing should extend sufficiently above the ground surface to prevent contamination from surface water and other environmental factors. Additionally, ensuring that the casing is securely sealed can prevent sediment and unwanted materials from entering the well. Industry research indicates that wells with well-installed casings have significantly lower failure rates and longer service life, averaging a lifespan of 20 years or more, as opposed to those with subpar installation practices that often fail within a decade.

Another important aspect is the selection of appropriate joining methods for the pipes. For example, using solvent welds for PVC pipes or threaded joints for steel pipes can significantly impact the overall integrity of the system. The United States Environmental Protection Agency highlights that leaks originating from improper pipe joining account for approximately 30% of water wastage in well systems. Hence, employing certified techniques and adhering to local regulations not only optimizes performance but also contributes to sustainable water management practices.

Maintenance Tips for Prolonging the Life of Water Well Pipes

Proper maintenance of water well pipes is crucial for ensuring a consistent and safe water supply. Regular inspections should be conducted to check for any signs of wear or damage, such as corrosion or leaks. By identifying these issues early, you can prevent more significant problems that might lead to costly repairs or even the need for a complete pipe replacement. Additionally, cleaning the pipes periodically helps eliminate mineral buildup, which can affect water quality and flow rate.

Another important aspect of maintaining water well pipes is ensuring they are adequately insulated, especially in colder climates. This prevents freezing and subsequent cracking that can occur during harsh winters. It's also advisable to monitor the water levels in the well, as excessive fluctuations can put stress on the pipes. Using proper installation techniques and materials designed for longevity can significantly enhance the lifespan of your water well system, ensuring that it performs efficiently for years to come. Regularly consulting with a professional about maintenance schedules can provide guidance tailored to your specific water supply system needs.

Related Posts

-

Understanding the Importance of Water Well Pipe Selection for Safe Water Access

-

Unlocking the Secrets of Sustainable Water Solutions with Advanced Well Drilling Supplies Leading the Market Transition

-

Understanding the Rapid Growth of PVC Supplies Market with Insights from Industry Trends and Data Analysis

-

The Evolution of Plastic Pipe: Sustainable Solutions for Modern Infrastructure

-

Essential Guide to Choosing the Right Water Well Supplies for Sustainable Water Management

-

Understanding the Benefits and Applications of PVC Water Pipes in Modern Plumbing Systems