2026 How to Choose Between Steel and PVC for Your Next Project

Choosing between steel and PVC for your next project can be challenging. Each material has unique benefits and drawbacks. Steel offers strength and durability, making it ideal for heavy-duty applications. It withstands extreme weather and heavy loads, which is crucial for long-term investments.

On the other hand, PVC is lightweight and easy to work with. It’s cost-effective and resistant to corrosion. This can lead to lower maintenance needs over time. However, its lack of strength compared to steel limits its use in some projects.

When deciding on steel or PVC, consider the specific requirements of your project. Reflect on your needs, budget, and long-term goals. Balance the pros and cons of steel PVC to find the best fit. Each choice has complexities that warrant careful thought.

Factors to Consider When Choosing Between Steel and PVC

When deciding between steel and PVC for your next project, consider the environment and durability.

Steel offers strength and longevity. It withstands extreme weather well. However, it is prone to rust if not treated properly.

PVC, on the other hand, is lightweight and resistant to moisture. It won't corrode, but it may not endure heavy impacts as steel can.

Think about the cost and installation process. Steel might require special tools and professional help. This can increase your budget.

PVC is often easier to install. You might save time and money with it.

Reflect on the specific requirements of your project. Do you need something sturdy and strong? Or light and easy to handle?

Each material has its pros and cons, so weigh them carefully.

Durability and Longevity: Steel vs. PVC Performance Metrics

When deciding between steel and PVC for your project, understanding durability and longevity is key. Steel is known for its strength. It can withstand harsh elements and heavy loads. However, it may rust if not properly treated. On the other hand, PVC is resistant to corrosion and decay. It is lighter and often easier to handle. But over time, UV rays can cause it to become brittle.

**Tip:** Consider your environment. For coastal areas, PVC might perform better due to its resistance to salt water. In industrial settings, steel often proves its worth by enduring more substantial stress.

Both materials have their pros and cons. Steel structures tend to last longer under heavy use. Still, they require maintenance to prevent rust. PVC may be a great choice for decorative elements but may not hold up under extreme conditions.

**Tip:** Think about your long-term needs and the specific challenges your project will face. Prioritize what matters most—is it strength or lightweight flexibility? Make your choice wisely.

Cost Analysis: Initial Investment and Long-term Expenses

When considering steel and PVC for your project, cost plays a crucial role. Steel may have a higher initial investment. The price of materials is often influenced by market demand. In contrast, PVC typically has lower upfront costs. However, it is essential to consider long-term expenses as well.

Long-term maintenance costs can add up quickly. Steel often requires regular upkeep, such as painting and rust prevention. This can lead to higher expenses over time. Conversely, PVC is generally low-maintenance, which can save money in the long run. Yet, it might not perform as well under extreme conditions.

You should also factor in potential replacement costs. Steel tends to last longer than PVC but can be more challenging to repair. If you opt for PVC, be prepared for possible replacements sooner. Weigh these elements carefully before making a decision. Your choice will impact your budget for years to come.

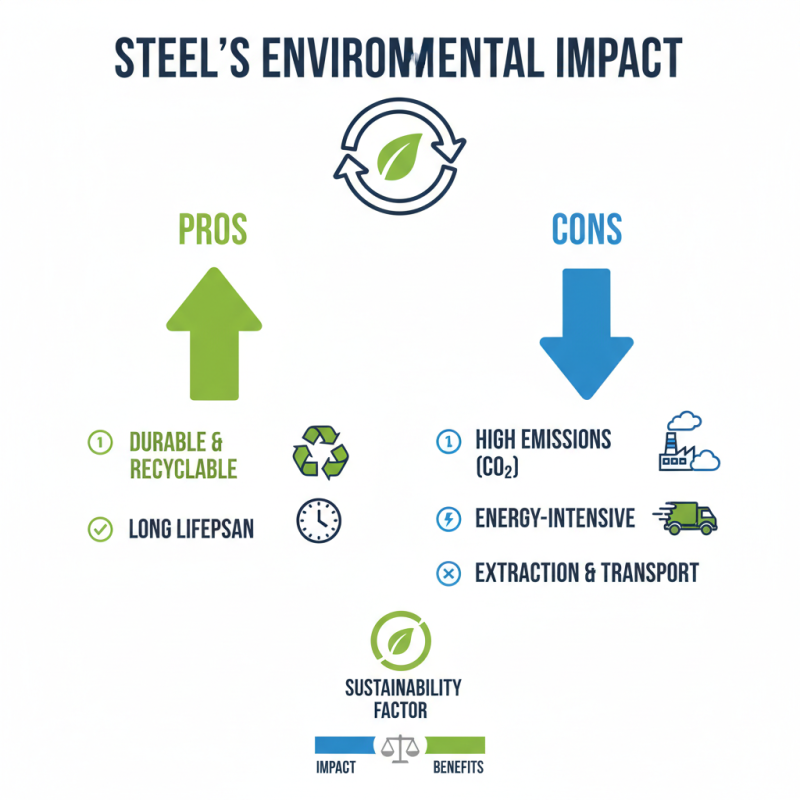

Environmental Impact: Sustainability of Steel and PVC Materials

When considering materials for your next project, the environmental impact is a crucial factor. Steel is highly durable and recyclable. Its production, however, emits significant greenhouse gases. Steel has a long lifespan, reducing the need for replacements. Yet, the energy-intensive process of extracting and transporting it can raise sustainability concerns.

PVC, on the other hand, is lighter and easy to work with. Its production process is less energy-consuming than steel. However, concerns about its long-term decomposition and potential toxicity remain. PVC products can last long but may contribute to pollution when discarded. This creates a dilemma for builders seeking the best sustainable options.

Choosing between steel and PVC requires careful thought. Consider the project's location and intended lifespan. Each material has distinct benefits and drawbacks. Sustainable building is complex. Finding the perfect balance between durability and environmental impact is not straightforward. Reflecting on these factors may lead to more informed choices.

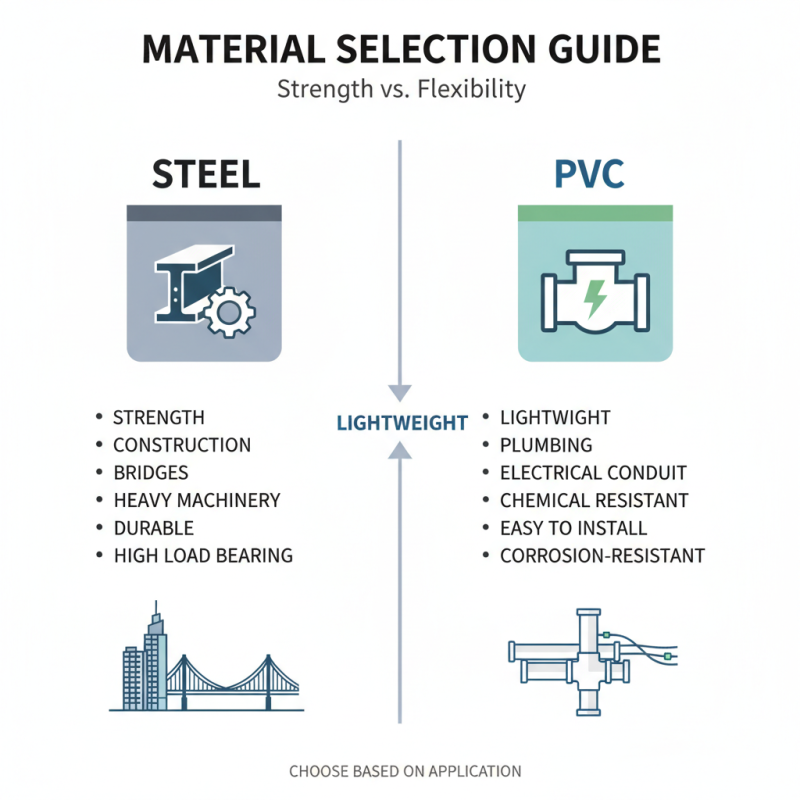

Applications and Use Cases: Best Projects for Steel and PVC

When deciding between steel and PVC for your next project, consider the applications. Steel is ideal for structures requiring strength. It’s used in construction, bridges, and heavy machinery. PVC, however, is often chosen for plumbing and electrical applications due to its lightweight nature.

Here’s a tip: analyze your project requirements closely. If durability and resilience against heavy loads are critical, steel may be your best choice. Conversely, for projects needing flexibility and ease of installation, PVC shines.

Think about the environment too. Steel is recyclable, promoting sustainability. PVC, while versatile, requires careful disposal considerations. Each material has its pros and cons, which might not be apparent at first glance. Reflect on your budget and long-term needs as well. This reflection might change your initial preference.

Related Posts

-

Top 5 Benefits of Using Steel PVC for Your Construction Projects

-

8 Essential Tips for Choosing Between Steel and PVC for Your Next Project

-

Essential Water Well Supplies: Ensuring Sustainable Water Access with 87% Efficiency in Groundwater Usage

-

2025 How to Choose the Right Well Casing for Your Drilling Project

-

2025 Top 10 PVC Tubes Innovations Driving the Market with 10 Billion Dollar Growth Potential

-

10 Essential Well Pump Supplies You Need for Optimal Water System Performance