How to Choose the Right Plastic Pipe for Your Plumbing Project

When embarking on a plumbing project, selecting the appropriate material is crucial for ensuring system longevity and performance. Among the various options available, plastic pipes have gained considerable popularity due to their lightweight nature, resistance to corrosion, and affordability. According to a recent report from the American Society of Plumbing Engineers, over 70% of plumbing installations in residential settings now utilize some form of plastic piping, a statistic that underscores the growing reliance on this versatile material.

Expert in the plastic pipe industry, Dr. Ellen Carter, emphasizes the importance of informed choices, stating, "Choosing the right type of plastic pipe can significantly influence both the efficiency and durability of plumbing systems." With a range of plastic pipe materials available—such as PVC, CPVC, and PEX—each type offers unique benefits and specific applications that every plumber and homeowner should carefully consider. By evaluating project requirements, environmental factors, and budget constraints, individuals can make informed selections that lead to successful plumbing outcomes.

Understanding the Different Types of Plastic Pipes Available

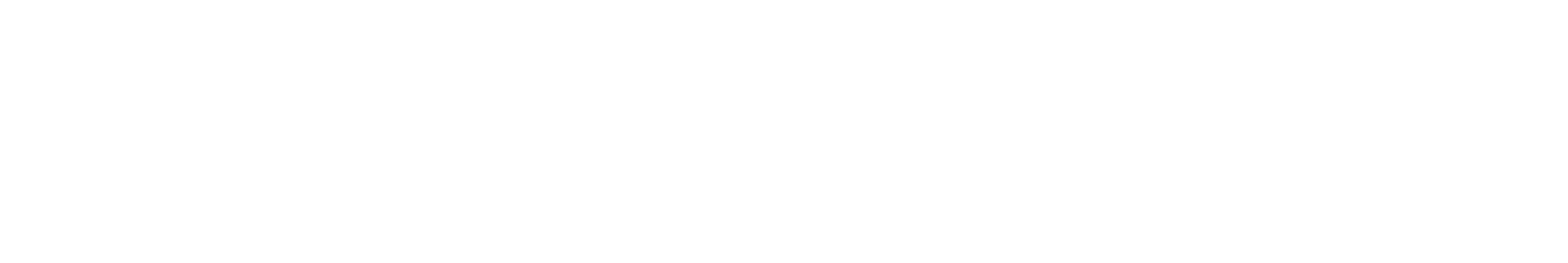

When selecting the right plastic pipe for your plumbing project, it's crucial to understand the various types available, as each offers distinct characteristics and benefits. The most common types of plastic pipes include PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), PEX (Cross-Linked Polyethylene), and ABS (Acrylonitrile Butadiene Styrene). According to a report by the Plastics Pipe Institute, the global demand for plastic pipes is expected to reach 48.3 million tons by 2027, highlighting the growing reliance on these materials in plumbing systems.

PVC pipes are widely used due to their affordability and resistance to corrosion. They are suitable for various applications, including drainage, waste, and vent systems. CPVC, on the other hand, can withstand higher temperatures and pressures, making it ideal for hot water applications. Meanwhile, PEX offers flexibility and ease of installation, especially in retrofitting projects, which has contributed to its increased popularity; a report from Markets and Markets indicates that the PEX market alone is projected to grow at a CAGR of 6.5% from 2021 to 2026.

ABS pipes are known for their strength and impact resistance, often utilized in underground installations. Each type has specific codes and regulations governing its use, so consulting local building codes is essential before making a choice. The comprehensive understanding of these plastic pipe types will not only guide homeowners and contractors in making informed decisions but also ensure compliance with industry standards.

Evaluating the Strength and Durability of Plastic Pipes

When evaluating plastic pipes for plumbing projects, strength and durability should be top priorities. Different types of plastic pipes, such as PVC, CPVC, and PEX, offer varying levels of resilience and resistance to environmental factors. For instance, PVC pipes are known for their rigidity and are highly resistant to corrosion and chemical damage, making them suitable for both underground and above-ground applications. On the other hand, PEX pipes are flexible and can withstand extreme temperature fluctuations, which is beneficial in regions with harsh weather conditions. Understanding the specific requirements of your plumbing project will help in selecting the right type of plastic pipe.

Another important aspect to consider is the pressure rating of the plastic pipe. This rating indicates how much pressure the pipe can handle before the risk of failure increases. For high-pressure applications, it is crucial to choose pipes with appropriate pressure ratings to ensure long-term performance. Additionally, examining the pipe's resistance to UV light and other external factors is vital, especially for installations exposed to sunlight. Ensuring that you opt for pipes engineered for durability can save time and costs associated with repairs or replacements in the future.

Strength and Durability of Common Plastic Pipes

This chart illustrates the tensile strength of various types of plastic pipes commonly used in plumbing projects. Understanding the strength and durability of these materials can help you make informed decisions for your specific needs.

Assessing Temperature and Pressure Ratings for Your Plumbing Needs

When selecting plastic pipes for plumbing projects, temperature and pressure ratings are critical parameters that must be carefully assessed to ensure optimal performance and longevity. According to the Plastics Pipe Institute, different types of plastic pipes, such as PVC and PEX, are designed to operate under specific temperature and pressure limits. For instance, standard PVC pipes are rated for a maximum operating temperature of 140°F (60°C) and pressure ratings that can vary based on the pipe diameter. Understanding these specifications helps avoid issues like deformation or failure under extreme conditions.

Moreover, the American Society for Testing and Materials (ASTM) provides guidelines that ensure pipes meet industry standards for pressure ratings. For example, PEX pipes are often used in residential applications due to their resilience and ability to withstand a range of temperatures, typically from -40°F to 200°F (-40°C to 93°C), with pressure ratings around 80-100 psi for hot water applications. By selecting the correct pipe based on these ratings, plumbers can enhance the safety and efficiency of their installations, minimizing the risk of leaks or service interruptions resulting from inappropriate material choices under varying environmental conditions.

Considerations for Pipe Size and Compatibility in Plumbing Systems

When selecting the right plastic pipe for your plumbing project, it is crucial to focus on pipe size and compatibility with existing systems. The diameter of the pipe directly affects water flow rates and overall efficiency. For example, smaller pipes may create higher pressure but could restrict flow in larger systems. Conversely, oversized pipes can reduce water pressure and lead to inefficiencies. Therefore, it’s important to match the pipe diameter with the specific requirements of your plumbing layout, including factors such as the length of the run and the number of fixtures being served.

Compatibility with fittings and other materials is another vital consideration. Not all plastic pipes are interchangeable; different types may have varied connection methods and chemical resistances. If you are working with mixed materials in your plumbing system, ensure that the plastic pipes you choose are compatible with existing pipes, joints, and fixtures to avoid leaks and failures. Additionally, consider the type of plastic in relation to the water being transported, as some varieties may not be suitable for hot water or may degrade over time when exposed to certain chemicals. Proper compatibility will ensure a more reliable and durable plumbing system, reducing the risk of future maintenance issues.

Selecting the Right Fittings and Connections for Plastic Pipes

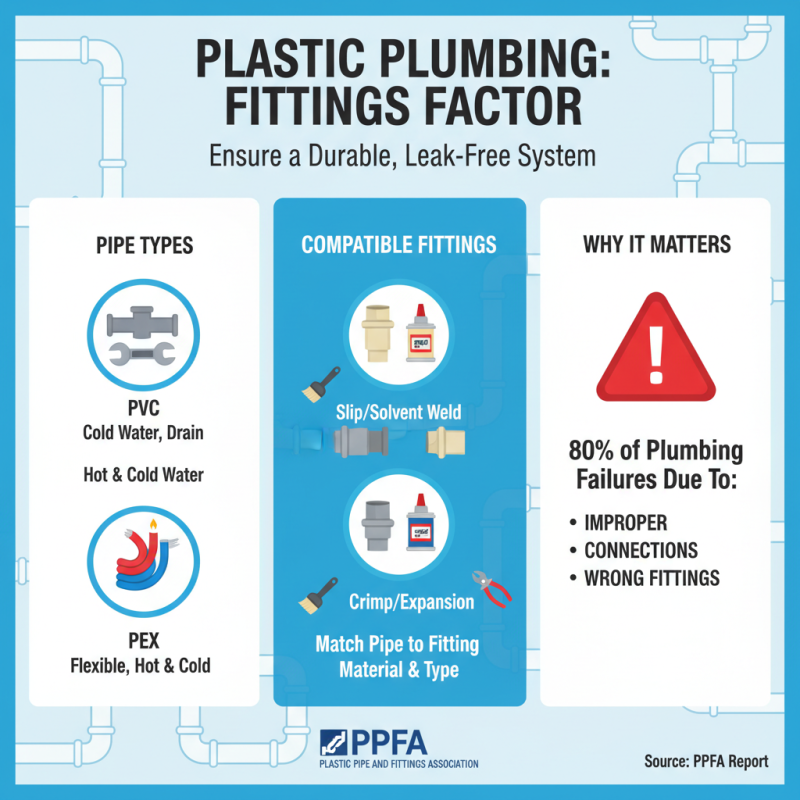

When selecting plastic pipes for your plumbing project, choosing the right fittings and connections is crucial for ensuring a durable and leak-free system. Different types of plastic pipes—such as PVC, CPVC, and PEX—require compatible fittings that can withstand the pressure and temperature of your specific application. According to a report by the Plastic Pipe and Fittings Association (PPFA), at least 80% of plumbing failures are attributed to improper connections, making the selection of the right fittings essential.

In terms of materials, ensure that your selected fittings match the pipe type and are appropriate for the intended use. For instance, PVC fittings are ideal for cold water applications, while CPVC fittings can handle hot water systems. PEX connections, often made with crimp or clamp systems, provide flexibility and ease of installation. It’s important to follow the manufacturer's guidelines regarding joint integrity and pressure ratings to maintain system reliability.

Tips: Always double-check the compatibility of fittings with the specific pipe material before installation. Consider investing in quality connectors that meet industry standards, as they can significantly reduce the risk of leaks. Lastly, don’t overlook the importance of using the right tools for installing the fittings; proper installation practices are key to ensuring a successful plumbing project.

Related Posts

-

The Evolution of Plastic Pipe: Sustainable Solutions for Modern Infrastructure

-

2025 Top Guide to Using 4 Inch PVC Pipe for Your Projects

-

Essential Water Well Supplies: Ensuring Sustainable Water Access with 87% Efficiency in Groundwater Usage

-

How to Choose the Right PVC Pipe for Your Home Project

-

4 Tips for Choosing the Right Steel Pipe for Your Project Requirements

-

Exploring the Latest Innovations in Pipe Supplies: What You Need to Know for Your Projects