How to Choose the Right PVC Pipe for Your Project?

Choosing the right PVC pipe is essential for any plumbing or construction project. PVC pipes are popular due to their durability and versatility. However, not all PVC pipes are created equal. Understanding the specifics can greatly impact your project’s success.

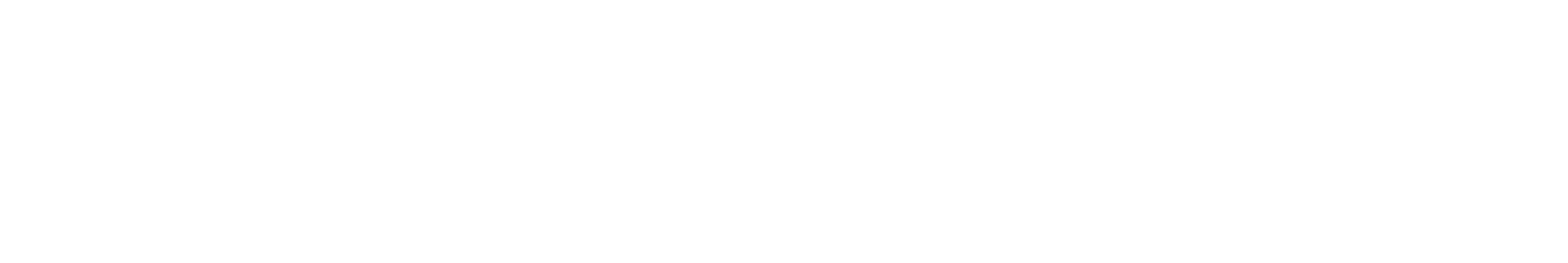

When selecting a PVC pipe, consider its size, thickness, and intended use. Different projects require different specifications. For instance, high-pressure systems need thicker walls. Getting these details wrong can lead to leaks or failures. Many people overlook these aspects, leading to costly mistakes.

Moreover, matching the right fittings and accessories is crucial. Compatibility issues can arise if you ignore this part. It's tempting to choose the first option available, but take time to evaluate. Remember, a little extra effort in the beginning can save you a lot of trouble later in your project.

Understanding the Different Types of PVC Pipes Available

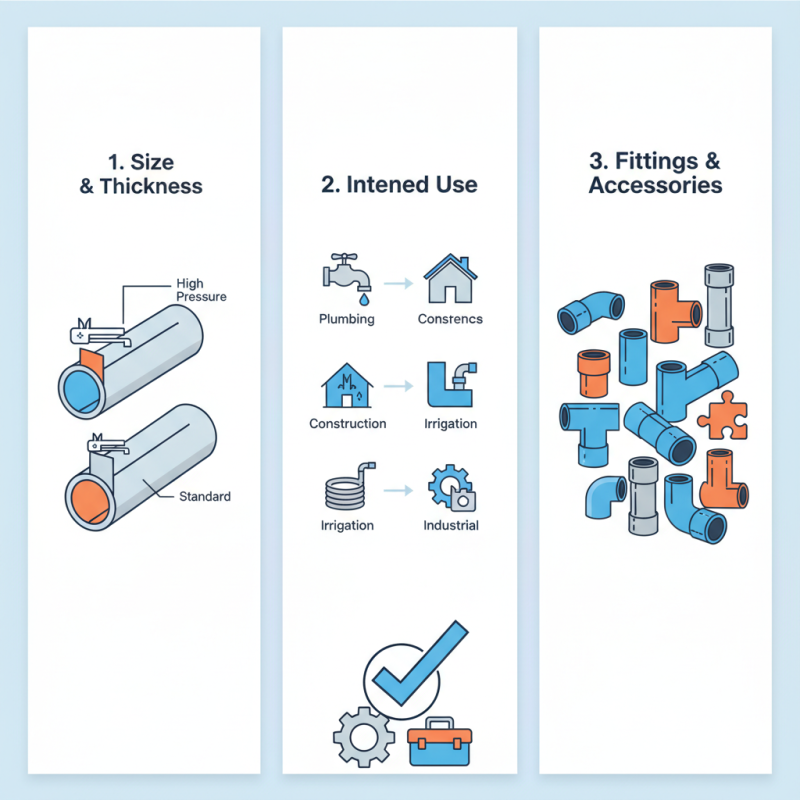

When selecting PVC pipe for your project, it’s essential to understand the types available. PVC pipes come in various grades and series, each suited for specific applications. For example, Schedule 40 pipes are standard in residential use, offering a balance of strength and cost. According to the Plastics Pipe Institute, the versatility of PVC pipes makes them ideal for a wide range of applications, from irrigation to plumbing.

There are different types of PVC, such as CPVC and Schedule 80. CPVC can withstand higher temperatures, making it suitable for hot water systems. Schedule 80 pipes are thicker and provide additional pressure resistance. Data from the American Society for Testing and Materials highlights that the correct selection dramatically impacts durability and performance.

Choosing the right type requires careful thought. While one type may suit a project, it could pose challenges in another context. For instance, using Schedule 40 in high-pressure applications might lead to failure. Not every type is perfect for all environments, so it's vital to match the pipe to the conditions it will face. This reflection can prevent future issues and ensure project longevity.

Factors to Consider When Selecting PVC Pipe for Your Project

When selecting PVC pipe for your project, consider several crucial factors. The diameter of the pipe is important. It determines the flow rate of fluids. If the diameter is too small, it causes restrictions. Too large means wasted space. You want the right balance for efficiency.

Material thickness is another factor to keep in mind. PVC pipes come in various schedules, like Schedule 40 and Schedule 80. Thicker pipes can handle higher pressures but may be overkill for simple drainage tasks. Weigh the project’s needs carefully.

Don’t forget about the environment where the pipe will be used. UV exposure can degrade some PVC. Also, consider temperature fluctuations that may lead to expansion and contraction. If your project involves chemicals, ensure compatibility with PVC. These choices can impact durability and longevity. Mistakes can be costly, so reflect on your selections.

Choosing the Right PVC Pipe for Your Project

This bar chart illustrates important factors to consider when selecting PVC pipes for your projects, including diameter, pressure rating, weight, and cost per foot.

Sizing Your PVC Pipe: Diameter and Length Considerations

Choosing the right diameter for your PVC pipe is crucial. A pipe's diameter affects flow rates. For water systems, a larger diameter may allow higher flow. However, consider the specific needs of your project. Too large a pipe can lead to inefficiencies. It may not maintain pressure as needed.

Length is another factor. Longer pipes can introduce more friction. This may reduce flow efficiency. Measure the distance carefully. Don’t underestimate the impact of bends and fittings, either. They can add resistance to the flow. Often overlooked, these factors can lead to big problems.

It's easy to get lost in calculations. You might not account for every angle or junction. Always double-check your measurements. If you're unsure, consult with a professional. They can provide insight that may save you time and resources. Every detail counts when it comes to choosing your PVC pipe.

How to Choose the Right PVC Pipe for Your Project? - Sizing Your PVC Pipe: Diameter and Length Considerations

| Pipe Diameter (inches) | Pipe Length (feet) | Recommended Use | Pressure Rating (PSI) |

|---|---|---|---|

| 1 | 10 | Draining | 200 |

| 2 | 20 | Irrigation | 280 |

| 3 | 30 | Sewage | 160 |

| 4 | 40 | Water Supply | 120 |

| 6 | 50 | Stormwater | 100 |

Assessing Chemical Compatibility for Your PVC Pipe Selection

When selecting PVC pipes, assessing chemical compatibility is crucial. Different chemicals can degrade PVC, affecting integrity. For instance, studies show that exposure to certain solvents can weaken the material. Some findings indicate that over 25% of PVC pipes fail due to chemical reactions.

Consider the environment where the pipes will be used. If you’re working with corrosive materials, you need a specific type of PVC. Not all PVC is created equal. Certain formulations can withstand harsh chemicals, while others cannot. Research has indicated that, without the right selection, installation failures can cost projects 15% more to rectify.

In some cases, users overlook compatibility, leading to unexpected consequences. Improper usage can result in leaks or bursts. These failures pose safety risks. Engineers often use a compatibility chart to evaluate potential risks. This not only improves safety but also extends the life of the installation. Understanding chemical resistance is not optional; it's essential for successful projects.

Installation Best Practices for PVC Piping Systems

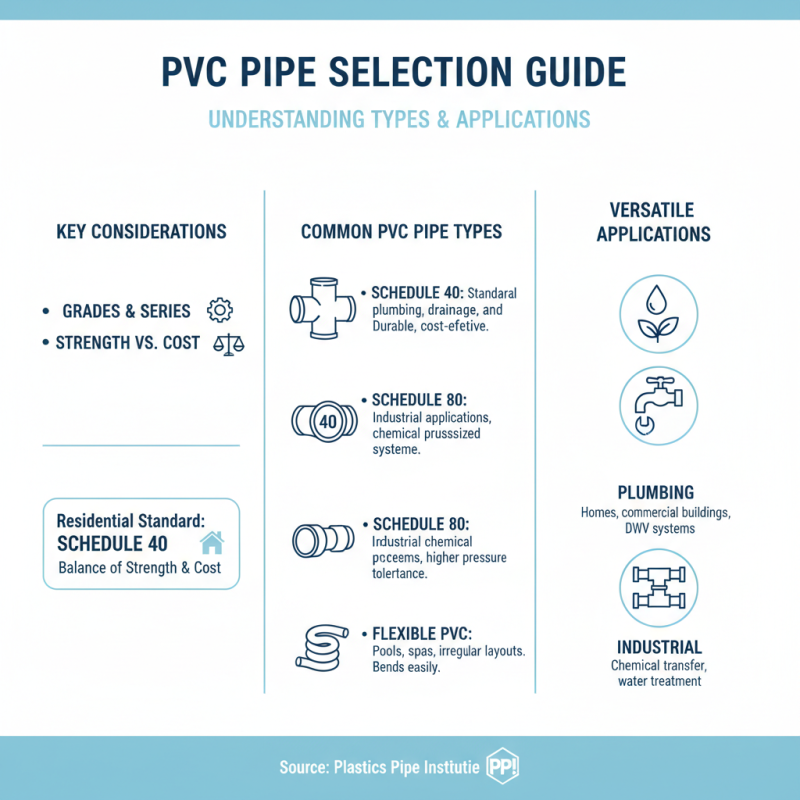

When installing PVC piping systems, proper practices are essential for performance and longevity. According to industry reports, nearly 80% of pipe failures can be traced back to improper installation. Ensuring the right cutting technique is critical. Use a pipe cutter for clean, square cuts. Jagged edges can lead to leaks later on.

Tip: Always deburr the cut edge. This minimizes the risk of damaging seals and fittings. Even a small burr can affect the entire system. Proper alignment is equally vital. Misaligned pipes can create stress points, leading to unexpected breaks. A level surface during installation can help achieve this.

Don’t forget about temperature considerations. PVC becomes less flexible in cold conditions. This can lead to brittleness and crack formation. Aim for installation at ideal temperatures to avoid this issue. Remember, even small mistakes can lead to significant problems down the line. It's important to be meticulous with every step. Inspect every joint and fitting thoroughly before covering them up. Attention to detail can save time and money later.

Related Posts

-

Understanding the Benefits and Applications of PVC Water Pipes in Modern Plumbing Systems

-

2025 Top Guide to Using 4 Inch PVC Pipe for Your Projects

-

Why Choose Plastic Pipe for Your Plumbing Needs and Benefits Explained

-

What is PVC Pipe and Its Uses in Construction and Plumbing?

-

8 Essential Tips for Choosing Between Steel and PVC for Your Next Project

-

Understanding the Importance of Water Well Pipe Selection for Safe Water Access