How to Measure 4 in PVC Pipe for Perfect Fit and Function?

In the world of plumbing and construction, precision is crucial. This is especially true when working with a "4 in PVC pipe". John Smith, a renowned expert in the PVC industry, once remarked, "Accurate measurements are the backbone of any successful plumbing project."

When measuring a 4 in PVC pipe, several details require attention. Many people make the mistake of relying solely on approximate measurements. This can lead to poor fittings and major frustrations. Every cutting and jointing task demands careful evaluation.

Consider the diameter, wall thickness, and overall length. Even small oversight can have big consequences. Ensuring a perfect fit is not just a matter of eyeing the numbers; it's about understanding the material and tools involved. Get it right, and your project will run smoothly. Get it wrong, and you could face leaks or costly rework.

Understanding PVC Pipe Sizes and Measurements

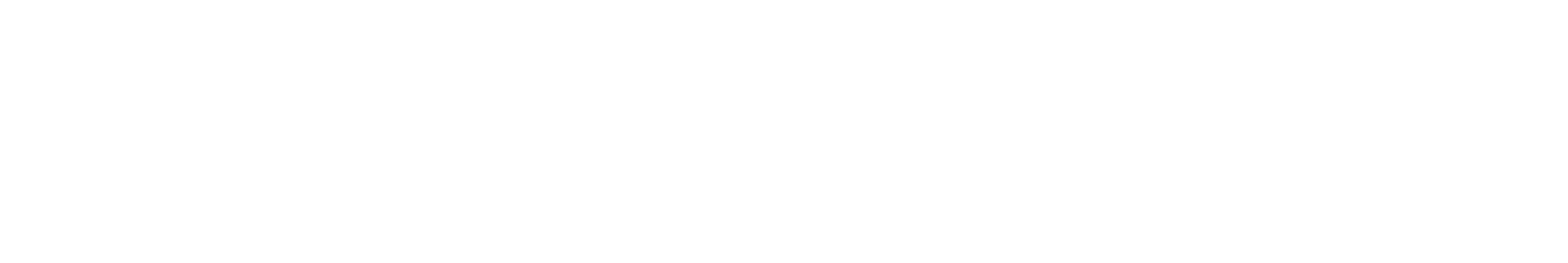

When measuring for a 4-inch PVC pipe, it's crucial to understand how pipe sizes are specified. PVC pipes are often labeled based on their nominal diameter, which, in this case, is 4 inches. However, the actual outer diameter is slightly larger. Many may assume that they can take measurements casually, but precise details matter greatly in plumbing or construction projects. You need to be exact.

A caliper or tape measure should be used to get accurate readings. Measure the outside diameter to understand how the pipe fits into fittings or connectors. Remember, each fitting will also have its unique measurements. In some cases, the fittings may even appear mismatched. This could lead to leaks and other issues. Always double-check the fit before finalizing any installation plans.

It's common to overlook the necessary measurements for wall thickness or the inner diameter of the pipe. Ignoring these specifications can lead to unexpected surprises down the line. If your setup involves bends or turns, consider the bending radius as well. Having everything mapped out creates a better outcome. Take your time with the process; a little patience can prevent larger headaches later on.

How to Measure 4 in PVC Pipe for Perfect Fit and Function?

| Measurement Type | Dimension (inches) | Notes |

|---|---|---|

| Nominal Size | 4 | Refers to the standard size designation for PVC pipes. |

| Outside Diameter | 4.5 | Typical outside diameter for a 4-inch PVC pipe. |

| Inside Diameter | 3.93 | This is the measurement for the inside of the pipe. |

| Wall Thickness | 0.12 | Average wall thickness for standard PVC pipe. |

| Length Options | 10, 20, 40 | Common lengths available for 4-inch PVC pipes. |

Tools Required for Accurate PVC Pipe Measurement

When measuring PVC pipe, accurate tools are essential. A good tape measure is crucial. It allows you to get precise measurements, avoiding errors. PVC pipes come in various diameters, and a standard tape measure can suffice for most projects. However, for more accuracy, consider using calipers. They can measure the outer diameter precisely, ensuring a snug fit.

A marking tool is also important. Use a fine-tip permanent marker or a scribe. Mark your measurements clearly, as a small mistake can lead to significant issues later. Misaligned cuts can compromise functionality. Every measurement counts, especially in plumbing or construction.

For larger projects, a digital measuring tool is beneficial. They reduce human error, providing instant feedback. According to industry reports, up to 30% of projects fail due to measurement mistakes. This highlights the importance of investing in good tools and taking time to measure correctly. Taking shortcuts can lead to costly reworks. Accuracy in the initial stages ensures perfect fits and smooth functions. Remember, precision is not just about the tool but the user as well.

Step-by-Step Guide to Measuring a 4-Inch PVC Pipe

Measuring a 4-inch PVC pipe is crucial for ensuring a perfect fit. Start by gathering your tools: a tape measure, a marker, and a straight edge. Make sure the pipe is clean. Dirt or debris can affect your measurements. Place the tape measure around the pipe for the outer diameter. It should read 4 inches.

Now, measure the inner diameter. Use your straight edge or another tool to help reach inside. Sometimes, people forget the importance of measuring both. Both dimensions serve different purposes. If you're using fittings, even a slight error can lead to leaks.

Finally, after your measurements, double-check them. Errors can easily slip by. An incorrect measurement can result in wasted materials or time. Adjust as needed, and take notes of your final figures. It’s a small step for perfect fitting!

Tips for Ensuring a Perfect Fit with PVC Fittings

When working with PVC fittings, a perfect fit is crucial for functionality. Begin by carefully measuring the outer diameter of your 4-inch PVC pipe. Use a tape measure for accurate results. Sometimes, it’s easy to overlook a slight variation in size. This can lead to inadequate seals and possible leaks.

Ensure you check the ends of the pipe for any burrs or debris. This is often ignored but can affect how the fittings slide on. A smooth, clean surface will help create a reliable connection. While assembling, apply gentle pressure. Overly forceful fittings may lead to cracks or deformities. Always keep an eye on the alignment. A misaligned connection may require a complete redo.

Before finalizing your project, do a dry fit. This means assembling the parts without glue. This step reveals potential issues early. If a fitting feels too tight or too loose, re-evaluate your measurements. Sometimes the best-laid plans need adjustments. It’s better to be thorough now than to deal with issues later on.

Common Errors to Avoid When Measuring PVC Pipes

When measuring 4-inch PVC pipes, precision is key. Many people make common errors that can lead to costly mistakes. One frequent issue is miscalculating the pipe diameter. It’s easy to overlook that 4 inches refers to the nominal size. The actual outside diameter may differ. Always check the specifications before cutting.

Another common mistake is neglecting to measure the space where the pipe will fit. Insufficient clearance can lead to frustration during installation. It’s essential to account for fittings and connectors. Measure twice before making any cuts, but even this step can be rushed. Errors in measuring can disrupt the entire project.

Relying solely on tape measures can lead to inconsistencies. Using a caliper offers more accuracy, but it can feel cumbersome. It's important to reflect on the tools you use. Don’t hesitate to seek assistance if uncertain. Even experienced DIYers can overlook simple details. Engaging a second pair of eyes can reveal overlooked measurements or miscalculations.

Related Posts

-

What are the benefits of using PVC pipe in construction?

-

Top 10 Uses of PVC Well Pipe for Water Distribution and Irrigation?

-

2025 Top 10 PVC Tubes Innovations Driving the Market with 10 Billion Dollar Growth Potential

-

How to Choose the Right PVC Pipe for Your Home Project

-

What is PVC Pipe and Its Uses in Construction and Plumbing?

-

Understanding the Rapid Growth of PVC Supplies Market with Insights from Industry Trends and Data Analysis