What is PVC Pipe and Its Uses in Construction and Plumbing?

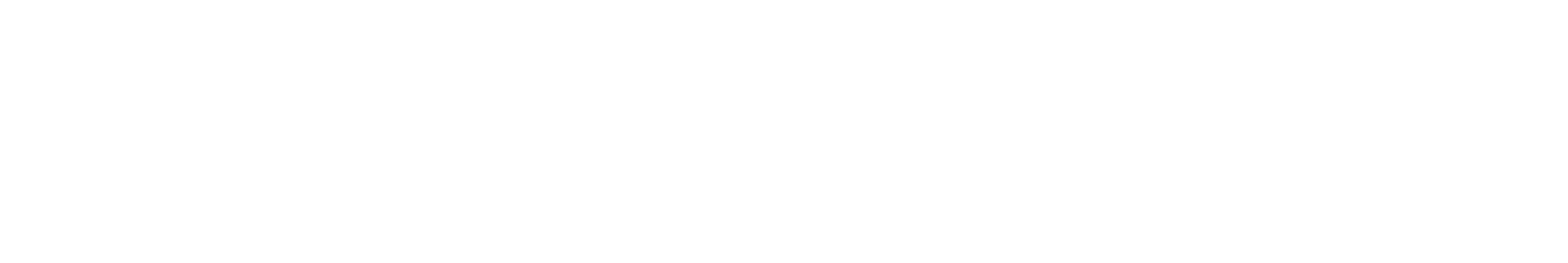

PVC pipe, or polyvinyl chloride pipe, is a popular material in construction and plumbing. Its durability and versatility make it an ideal choice for various applications. Many builders and plumbers utilize PVC for water supply lines, drainage systems, and ventilation. It’s lightweight, making it easy to handle and install.

However, not all PVC pipes are created equal. Some may not withstand extreme temperatures or pressure. It's important to choose the right type for each project. Sharp edges may pose safety hazards during installation. Proper handling is crucial. PVC pipe can also be sensitive to UV light, leading to deterioration if exposed.

Despite these concerns, PVC remains widely used. Its affordability compared to metal pipes is appealing. The variety of sizes and shapes adds to its functionality. As construction demands evolve, so do PVC pipe applications. Understanding its advantages and drawbacks can lead to better construction decisions. Careful consideration will ensure lasting results.

What is PVC Pipe? A Comprehensive Overview

PVC pipe, or polyvinyl chloride pipe, is a widely used material in construction and plumbing. It is lightweight, durable, and resistant to corrosion. These qualities make it ideal for various applications. It comes in different diameters, allowing flexibility for different project needs. The smooth interior makes water flow more efficiently, which can be a major advantage in plumbing systems.

In construction, PVC pipes are commonly used for drainage and venting. Their longevity is notable. They rarely need replacement, reducing long-term costs. However, some may find the installation process quite challenging. Misalignment can lead to leaks, which is frustrating. Regular checks and maintenance are crucial to ensure they perform optimally.

PVC pipe is also utilized for electrical conduits due to its insulating properties. It keeps wires safe from moisture and physical damage. Yet, it can be tricky to handle. Cutting it requires precision. A rough cut can lead to complications. Not everyone has the experience or tools needed for a proper job, creating potential problems down the line. Therefore, careful planning and execution are essential in using PVC pipes effectively.

The Composition and Properties of PVC in Construction

PVC, or polyvinyl chloride, is a widely used material in construction and plumbing. Its versatile composition contributes to its popularity. PVC is produced by polymerizing vinyl chloride monomer. This process creates a thermoplastic with excellent resistance to corrosion, chemicals, and moisture. According to industry reports, the global PVC market is expected to reach $60 billion by 2027, reflecting its growing importance.

The properties of PVC make it an excellent choice for pipes in plumbing systems. PVC pipes are lightweight, durable, and easy to install. They don’t rust like metal pipes. This can lead to lower maintenance costs over time. However, the rigidity of PVC means it can be prone to cracking under extreme pressure. Proper installation techniques are essential. Many plumbers recommend regular inspections.

Tip: Always choose the correct size of PVC pipe for your project to avoid unnecessary pressure changes.

In construction, PVC is used not only for pipes but also for windows, doors, and flooring. Its insulating properties help improve energy efficiency. Studies show that homes using PVC windows save on heating costs. Yet, environmental concerns exist regarding PVC production and disposal. Finding a balance between utility and sustainability is vital.

Tip: Consider using recycled PVC products to minimize environmental impact while maintaining the benefits of this versatile material.

Advantages of PVC Pipes in Plumbing Systems

PVC pipes are widely used in plumbing systems due to their many advantages. According to a recent industry report, these pipes account for around 75% of the global plumbing market. Their lightweight nature makes installation easier and reduces transportation costs. Contractors favor PVC because it is easy to handle and cut.

Durability is a significant advantage of PVC pipes. They resist corrosion and are not affected by chemicals commonly found in wastewater. This resilience can lead to a longer lifespan, often exceeding 50 years under ideal conditions. However, some reports highlight that UV exposure can weaken PVC over time, so proper installation is crucial.

Cost-effectiveness is another benefit. PVC pipes generally have lower initial costs than metal pipes. Data shows that PVC can be up to 25% cheaper than copper solutions. Nonetheless, users should be cautious about brittle failure in cold temperatures. That’s a potential concern when considering PVC pipes for outdoor applications. While they perform well, assessing the right environment for their use is essential.

Industry Standards and Regulations for PVC Pipes

PVC pipes are widely used in construction and plumbing due to their durability and cost-effectiveness. However, understanding the industry standards and regulations governing their use is crucial. The American Society for Testing and Materials (ASTM) sets specific standards for PVC materials. According to ASTM F891, PVC pipes must meet stringent criteria for performance and safety.

PVC pipes should be manufactured according to the standards of the American National Standards Institute (ANSI). These regulations ensure that the pipes can withstand high pressure and temperature variations. Studies show that compliance with these standards reduces the risk of pipe failure. For example, data from the Plastic Pipe Institute indicates that properly regulated PVC pipes last over 50 years in typical applications.

Yet, challenges remain in the industry. Some manufacturers may overlook quality control in favor of lower costs. This practice can lead to weakened pipes that don’t meet safety benchmarks. Regular inspections and adherence to guidelines are necessary but often ignored. Industry reports highlight that nearly 15% of PVC products fail to meet the required standards, raising concerns about reliability in critical plumbing systems.

Usage of PVC Pipes in Construction and Plumbing

Common Applications of PVC Pipes in Residential and Commercial Construction

PVC pipes are widely used in both residential and commercial construction. These pipes offer versatility and durability for various applications. Their lightweight nature makes them easy to handle and install. Many constructors prefer PVC due to its cost-effectiveness.

In residential settings, PVC pipes are commonly used for drainage systems. They efficiently channel waste water away from homes. They also serve in venting applications. This is crucial for proper drainage and prevents sewer gases from entering living spaces. In contrast, in commercial buildings, PVC pipes are often used for plumbing systems. Their resistance to corrosion is advantageous in large-scale installations.

It's important to consider potential drawbacks. PVC can warp or become brittle when exposed to extreme temperatures. Installation methods may also vary, leading to confusion. Inspecting connections and joints regularly can prevent leaks. Careful planning is essential to ensure optimal performance.

Related Posts

-

How to Choose the Right PVC Pipe for Your Home Project

-

Understanding the Rapid Growth of PVC Supplies Market with Insights from Industry Trends and Data Analysis

-

2025 Top 10 PVC Tubes Innovations Driving the Market with 10 Billion Dollar Growth Potential

-

2025 How to Choose the Best PVC Well Pipe for Your Water System

-

2025 Top Guide to Using 4 Inch PVC Pipe for Your Projects

-

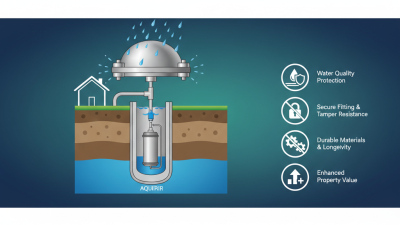

Top 10 Best Well Caps for Your Property Protection and Water Quality